In the world of pneumatic tools, some tools stand far above the rest. The Sioux model 5200 air tool well respected in professional shops, on the factory floor, and in the most serious of DIY installations. In this article, we’ll detail its unique features, appropriate usage, maintenance and evaluate its suitability.

What Is Sioux Model 5200 Air Tool?

In industrial and other workshops, Sioux Model 5200 categorized as an air tool and more specifically a pneumatic surface preparation tool (which could also referred to micro as finishing or surface prep tools). This ensures optimal and accurate prep cycles while sanding, finishing, polishing, or surface and edge deburring, giving you clean results ideal for prep assembly, coating, or painting on painting surfaces rather than Raw surfaces.

Generic air tools cannot compete with the 5200. The Sioux Model 5200 developed and designed for precision, comfort, and durability, all while remaining in a compact size, a trademark of Sioux air tools. It is ideal for smooth surface and accurate control tasks.

To summarize, Sioux Model 5200 air tools ensures ease of use while getting the job done, which is why it will always sought after.

The Heritage of Sioux Tools

As a starting point, examining the tool’s heritage helps explain its prestige and value.

- Sioux Tools, Inc. a well known American producer of industrial pneumatic tools. The company’s product lines include drills and about a dozen other types of tools like finishing, abrasive, and specialty air tools.

- Their technology and craftsmanship defined by the catalogs focus on a certain power-to-weight ratio, which the most critical ratio to consider for balanced tools, and those attributes carried into the Model 5200.

- Over time, the company Sioux has improved their designs based on the suggestions and insights of industrial users to ensure that the tools the company provides are reliable and durable in practice and not just on paper.

This is the reason the 5200 exists. It part of a heritage that is a legacy to industrial grade tools that trusted all over the globe.

Technical Specifications & Key Features

A model 5200 Sioux better understood by looking at its specifications and features. (Disclaimer: Full official specifications may vary. Certain specs have derived descriptions and comparisons made available.)

Typical Specifications

| Parameter | Estimate / Description |

|---|

| Tool Type | Micro surface prep / finishing pneumatically powered |

| Operating Pressure | Often around 90 PSI (gauge reading at the tool) in real use |

| Construction | Lightweight aluminum housing + quality internal gears |

| Gear System | Compact, efficient gearing (e.g. planetary or multi-gear) |

| Ergonomics | Rubberized grip, minimized vibration, compact form factor |

| Maintenance Port | Zerk grease fitting for easy lubrication |

| Applications | Sanding, surface prep, deburring, finishing |

Distinctive Features

- Despite its compact size, the 5200 is capable of an impressive amount of torque. This proves to be ideal for surface work that is both delicate and demanding.

- The internal parts are made from durable materials, while the engineering is designed to minimize wear and extend service life.

- Maintenance made easier with simple access points, grease fittings, and fewer intricate components.

- The correct abrasive pads or attachments will enable it to polish or moderately remove materials effectively.

- The 5200 suits sanders or air grinders and lies just above basic ones and below heavy-duty industrial equipment.

Why Professionals Choose It

The Saab Model 5200’s reputation derived from its performance and reliability. Many professionals use it based on the following reasons.

Time is Money

For every minute spent in the workshop, adding time to the 5200’s surface preparation tasks enables you to finish the task much easier. With the help of hand tools or less capable air tools, use and gain consistency and power to prep the surface.

Surface Quality

The difference between a good and great surface during finish work is very subtle. Controlled swirls with less mark removal help the tool deliver surface operation with great quality the smoother it runs with help from the torque control.

Work Fatigue

Long shifts become more comfortable to helps operate with great control and hold the tool in position due to the lowering vibration features, ergonomic design, and lightweight.

Low Cost of Ownership

Possible higher cost is countered by gaining earnings through durability offsets, and long life coupled with low maintenance costs.

Support and Reputation

Repair and maintenance countered with Sioux’s reputation and support network providing service centers along with their manuals.

Example To Illustrate:

At one aerospace parts shop, a technician once tried a cheap rotary sander on a critical fuselage panel. In under 10 minutes, the tool fell behind, left spiral patterns, and raised the temperature of the metal. Then they switched to a Sioux 5200 – in a few minutes, the surface was even and smooth, and primed. That level of dependability under pressure is the type of service that earns loyalty.

Real-World Applications & Use Cases

Recognizing where this tool actually excels will allow you to determine if it will benefit you.

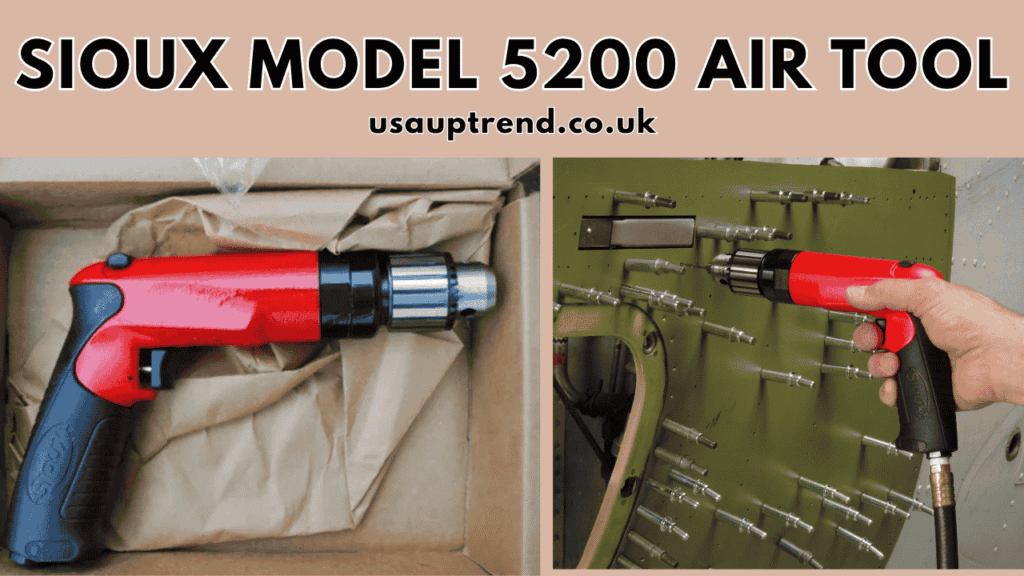

Automotive & Body Shops

- Safely removing old paint or coatings near seams

- Removing filler or primer

- Deburring internal panel welds or edges

- Finishing metal parts to be painting

Aerospace & Aviation

- Finishing aircraft skins where uniformity is critical

- Deburring machined parts

- Preparing parts for protective coatings or anti-corrosion

General Manufacturing & Metal Fabrication

- Removing burrs from stamped or cut parts

- Pre-final coatings surface finishing for assemblies

- Polishing welds or blending seams

Light Renovation & Woodworking

- Mainly focused on metal, the 5200 excels and fine sanding wood or composite where low-vibration tools required.

Maintenance and Workshops

When a workshop contains mixed repair and surface preparation work, one of the greatest multitasking tools an artisan can have an air powered tool that can complete surface tasks instead of several different specialty tools.

Step by Step Workflow: Using the Sioux Model 5200

The following the sequence of steps that can be followed while ensuring maximum productivity and optimal safety as well as ensuring longevity of the tool.

Preparation & Safety

- Put on Thread and Safety Protection Equipment that consists of protective eyewear, gloves, earmuffs, and a mask.

- Analyze structure of the surface that to worked on and remove any bulk debris, dust, and rust.

- Gather the required abrasive disk, (For example: grit, backing pad and crepe, shape.) lag types that are to be used.

Attaching Equipment and Supplying Air

- Join the air supply hose to the tool’s inlet and check the hose for proper size and make certain the air is free of moisture and dust.

- Ensure the pressure regulator’s settings so that the tool sees ~90 PSI (or the recommended pressure) under load.

- For Sioux or the handout instructions, ADD ONE OR TWO DRIPS of air tool oil to the inlet before the start if it’s advisable.

Starting Slowly and Testing

- For the first run, the tool is loaded, and it should be run without any work (no contact), and if it works smoothly, then it is safe to say the tool works as it should and is functioning.

- Then take the tool to a piece of scrap or an area that is concealed and apply the slightest of pressure to test it, should relief be required, then relief should apply.

- It tool feels stuck or shaky, reduce the applied pressure or the speed.

Work the Surface

- Strokes should be gentle, consistent, and overlapping.

- The tool should lifted and not pressed against the material. If pressed too hard, the tool could overheat or burn the material.

- The tool should cleaned every few minutes to ensure it does not clog.

Finish and Clean

- Once the pass done, the tool should retracted and allowed to spin for some time. Then and only then should the tool switched off.

- The tool should cleaned carefully.

Storage and Lubrication

- The tool should kept in a dust free place to allow, free from rust or corrosion.

- The procedure and steps outline above enables the user to operate the 5200 without undue wear or extremes on the tool.

- Most tools, including the 5200 from Sioux do require proper care and maintenance to ensure long lasting service.

Also Read: Wellness Technology Bypulsetto

Maintenance & Care — Best Practices

A high-quality tool like the Sioux Model 5200 deserves proper care. Here’s how to keep it in top shape:

Daily and After Each Use

- The tool should blown out with compressed air to prevent the clogging of internal airways.

- The tool should kept in a manner that allows for easy access to ensure the exterior is not dusty.

- Add tool oil through the inlet every so often (if prescribed).

Weekly

- Tighten and check the balance of the screws and housing for any signs of slack.

- Check the coupling or the abrasive pad alignment and its proper placement.

Monthly / Periodic

Grease the internal gears through the Zerk grease fitting.

- If the construction permits it, take apart the housing and look for any signs of wear, scoring, or other damage.

- Any internal parts that are worn (bearings, seals) should be checked and replaced to prevent major issues.

- Check o-rings, seals, and couplings for any leaks.

Long-Term

- If power starts to fade, it may be time for overhaul, so in this case, keep a log of the hours used.

- Only Sioux replacement parts should be used to maintain proper fit and use.

- The 5200 can serve for many years and thousands of hours by following a regular scheduled maintenance plan.

Sioux Model 5200 Air Tool Comparison With Other Air Tools

- An useful way to consider the Sioux Model 5200 is by comparing it to other similar tools.

- Tool Type Strengths Weaknesses Where 5200 Dominates

- Cheap rotary air sander Price Accuracy Finish

- Heavy industrial surface prep machines Power Size Maneuverability

- Electric grinders or polishers Convenience Heat Use

- Other premium air finishing tools Support Branding Sioux

- The 5200 is positioned nicely between beginner tools and industrial machines; it delivers finishing on the premium side while still possessing enough versatility for a number of shop applications.

Tips for Buying & What to Watch Out For

- 30 day money back guarantee is not a promise that the product is of low quality, rather it is a statement to encourage not buying the Sioux Model 5200.

- Always buy from the authorized sellers – Avoid scammers.

- The condition of the item must be verified – Used equipments.

- Request for the document list stating readily available parts – Warranty.

- Accessories must be verified – Adapters, backing plates, and abrasives.

- Review any contracts to familiarize yourself with coverage under warranty and any terms related to claims.

- To maximize the functionality of opt trial or demo versions if applicable.

- Tackling these issues will help mitigate possible risks and bolster your confidence towards the investment.

Common Questions (FAQs)

What is the recommended air supply for the 5200?

It is Approximately 90 PSI, based on the on-tool gauge and under working conditions.

Will the 5200 take off a heavy weld or a thick coating?

It is more geared towards light/moderate finishing, smoothing, or preparation. Any heavy removal will likely need the use of a bigger tool or several passes.

Is it safe on thin metal?

Yes, if the right tool is applied with light pressure and the right abrasive without risk of gouging.

Does it work on wood or composites?

Yes, lighter work and finishing metal is the primary focus of the tool.

How often should I grease it?

It may vary based on use, but in acceptable ranges, regular grease intervals on a weekly or monthly basis, more so after extended heavy use suggested.

Are spare parts easy to obtain?

Yes. Thanks to Sioux’s legacy, lots of distributors and service centers have parts in stock. It is best to check before buying any part.

Conclusion: Is It The Right Tool For You?

The Sioux Model 5200 air tool is not just any old tool that comes in a generic design. It a precisely designed air tool that caters to the needs of the user in regard to industrial finishing. If the work you do focused on surface prep, metal finishing, deburring, or you need to prepare a coating in a workshop, manufacturing or repair plant, then the 5200 is the best option available.

Nonetheless, if your requirements are basic, then you may not need to invest in this product. Consider the cost vs benefit ratio throughout your industry. For many industrial settings, the 5200 a delight because it is quick, efficient, and gets the work done.

Read More Topics on UsaUptrend